Laser cut metal signs are a prominent feature in various settings, from businesses and public spaces to personal decor. The precision of laser cutting technology allows for intricate designs and durability, making them a favored choice for both indoor and outdoor signage. They cater to a wide range of purposes, including commercial branding, wayfinding, and artistic installations, embodying both functionality and aesthetic appeal.

Crafters and professionals produce these signs utilizing materials like aluminum, steel, and copper to ensure longevity and resistance to environmental factors. The customization options offered by craftsmen and manufacturers, such as Smith Steelworks and ShieldCo, are extensive, with clients able to select from an array of metal finishes, colors, sizes, and mounting options to meet their specific needs.

The creation process involves high-quality lasers which precisely cut the design from metal sheets. The cut pieces can then receive additional treatments like powder coating to enhance their appearance and protective qualities. Personalized metal signs are not only a practical choice for their visibility and resilience but also for their potential to incorporate branding and personal style into a physical location.

Designing Your Laser Cut Metal Sign

When designing a laser cut metal sign, one must consider the artistic elements, choose the appropriate material, and understand the digital design process. Each step plays a critical role in creating a sign that meets both aesthetic and practical standards.

Artistic Considerations

Artistic flair is fundamental in making a laser cut metal sign stand out. The custom design must embody the brand’s image or the personal style it represents. Key visual elements such as complexity, imagery, and thematic coherence should be aligned with the sign’s intended message. Artists must consider negative space---the areas where metal isn’t present---as this will define the sign’s look just as much as the metal itself.

Material Selection

Selecting the right material is essential for both the look and longevity of the sign. Common options include:

- Carbon steel: durable and suitable for both indoor and outdoor signs.

- Stainless steel: offers a sleek, modern finish and corrosion resistance.

- Aluminum: lightweight and highly resistant to corrosion, ideal for outdoor applications.

- Brass: provides a classic look with golden tones.

Each material comes with its unique properties, affecting the sign’s final appearance and resistance to environmental factors.

Digital Design Process

Transforming an artistic concept into a sign begins with the digital design process. Designers typically use software like AutoCAD to create a precise layout of the sign. Files are often saved in formats such as DXF, EPS, or SVG, which are compatible with laser cutting machines. Digital design allows for the personalization of every aspect of the sign, ensuring the final product is a true reflection of the custom design provided by the customer or artist.

Manufacturing and Techniques

This section focuses on the intricacies of creating metal signs using laser technology, exploring the precision of the cutting process, the various finishing options including powder coating for enhanced durability, and the overall quality achieved through these methods.

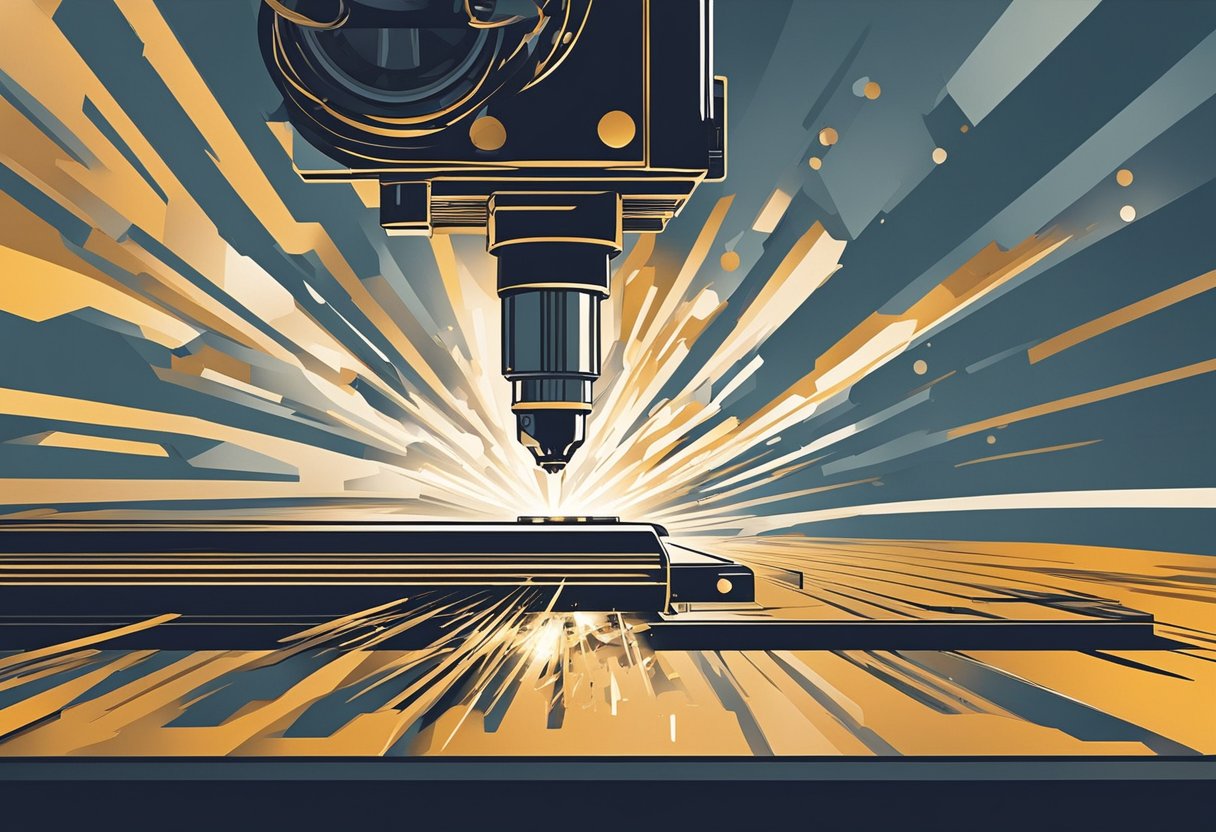

Laser Cutting Process

The laser cutting process starts with directing a high-powered laser beam onto a steel surface to make precise cuts. These lasers can vaporize materials or create clean cuts, allowing for intricate designs and high levels of precision. For example, some machines can handle metal thicknesses ranging from 0.2 to 1.0 inches, making them versatile for different sign requirements.

Finishing Options

Once cut, the metal signs can be finished with various options to enhance their appearance and durability. A popular choice is powder coating, a technique that involves applying a dry powder to the steel surface and then curing it under heat to form a tough, corrosion-resistant layer. Customers can choose from multiple colors and finishes to suit their branding needs.

Quality and Precision

High-quality and precision are the hallmarks of laser-cut metal signs. The enhanced control of the laser cut technique allows for production of complex shapes with clean, crisp edges. This level of detail contributes to the sign’s professional look, making it a durable and long-lasting choice for both businesses and homes.

Installation and Maintenance

Proper installation and consistent maintenance are crucial for ensuring that laser cut metal signs maintain their aesthetic and structural integrity. Whether for a business facade or home decor, attention to these details will support longevity and visual appeal.

Mounting Solutions

For mounting metal signs, one must consider the sign’s weight, size, and location. Businesses typically utilize stand-off mounts for a bold and professional look. These mounts hold the sign away from the surface, creating a drop shadow and allowing for light to pass behind, which can be particularly effective with laser cut metal signs.

For home address signs or decorative pieces, simpler mounting solutions like flush mounts or French cleats may suffice. Rustic signs might use chains or natural rope for a more rustic look. It is crucial to use appropriate anchors for the wall material to ensure the sign’s stability.

Mounting Methods:

- Stand-off mounts: For business and outdoor signs.

- Flush mounts: For indoor and smaller signs.

- French cleat system: For easy installation and alignment.

- Chains/rope: For adding a rustic feel.

Materials for Mounts:

- Stainless steel: Resistant to rust, ideal for outdoor use.

- Powder-coated steel: For colored or themed signs.

- Brass fittings: Adds a vintage look.

Longevity and Care

Long-term care for metal signs depends heavily on the material and environment. Signs made from stainless steel or aluminum typically resist corrosion well, perfect for most settings. Outdoor signs made from materials such as cor-ten steel develop a stable rust-like appearance that protects against weathering, making them popular for both their rustic aesthetic and durability without requiring much maintenance.

Maintenance Tips:

- Cor-ten steel: Leave untreated to form a protective patina.

- Stainless steel/aluminum: Clean regularly to maintain shine and prevent grime accumulation.

- Powder-coated finishes: Check for scratches periodically to prevent rust.

For address signs or other signs exposed to harsh weather conditions, periodic cleaning with soapy water can prevent dirt accumulation. In coastal areas, one may need to apply protectant coatings to avoid salt corrosion. Always follow manufacturer recommendations for specific care instructions.

Commercial and Personal Uses

Laser cut metal signs serve a diverse range of applications, both in commercial settings and personal spaces. Their durability and precision make them a top choice for various signage needs.

Business and Office Signage

- Business signs: Laser cut signs are essential for creating a professional image, often seen enhancing business fronts and office signs. They are fabricated to withstand environmental elements, making them suitable for both indoor and outdoor use. Companies like ShieldCo specialize in custom metal logo signs, often used in lobbies and on building exteriors to establish brand presence.

- City signs: Municipalities opt for laser cut signs when indicating city parks or installing cemetery signs, owing to their longevity and the ability to withstand weathering. They are also an ideal choice for city signs that require the high visibility and distinctiveness that laser cutting can provide.

Home and Outdoor Signage

- Home decor: Increasingly popular for home decor, laser cut metal signs are used to personalize living spaces. These signs can adorn walls, turning a simple logo or text into a statement piece.

- Yard signs: In personal outdoor spaces, yard signs and estate signs offer a custom touch to signify home ownership or to denote special areas in city parks. Options available by vendors such as Superior Laser Cutting allow for completely customized and weatherproof outdoor signs.

- Wall art: Surfaces in restaurants and homes alike are often embellished with intricate laser cut wall art, lending a unique and modern appeal to any space.

Laser cut metal signs play integral roles in both commercial and personal environments, offering a blend of aesthetic appeal and functionality.

Purchasing and Custom Orders

When looking to buy metal signs, consumers can choose between ready-made options or placing custom orders to meet their specific needs.

Buying Ready-Made Signs

Ready-made signs offer a convenient option for those seeking quick solutions or standard designs. These signs can range from handmade pieces to vintage treasures, readily available on global marketplaces such as Etsy. Sellers in these online platforms offer an array of options, from custom metal signs to decorative pieces, often with the benefit of free shipping.

Creating Custom Orders

For those requiring a unique touch, creating custom orders allows for personalization. Customers can collaborate with creative entrepreneurs, specifying details like size, font, and material. Custom laser cut metal signs are crafted to order, with some sellers providing made-to-order items tailored to any specification. This level of customization can transform basic signage into special goods reflecting the buyer’s exact vision. Control the details of your metal sign to give it a personalized look that suits your brand or personal taste.

Considerations for Special Features

When creating laser cut metal signs, certain special features can significantly enhance the visual impact. These features include advanced lighting techniques and dynamic multilayered compositions.

Lighting Enhancements

Lighting brings a sign to life and can alter its appearance dramatically. Backlighting, for example, creates a halo effect around the letters or design, providing a high-contrast look especially noticeable at night or in dimly lit areas. Front lighting, on the other hand, directly illuminates the sign’s surface, which can be beneficial for detailed graphics and colorful signs. One must consider the type of lighting source, whether LED or neon, as each offers different levels of brightness and energy efficiency.

Multilayered Designs

Multilayered designs involve stacking multiple layers of metal to create a three-dimensional effect. Incorporating multiple layers not only adds depth to the sign but also opens up possibilities for complex and detailed artwork. Designers should carefully balance the visual complexity with readability, ensuring that the sign conveys its message effectively. When considering a single layer versus multiple layers, they should account for the additional weight and installation requirements that Multilayered Designs would necessitate.